Schöpfen Sie das Potenzial Ihres Produkts mit unseren One-Stop-Lösungen aus!

+86-755-83222882

ERHALTEN SIE ZITAT

Kompressionsformen vs. Spritzgießen: Was sind die Unterschiede?

Wenn es um die Herstellung von Gegenständen aus Kunststoff geht, fragen Sie sich vielleicht, ob Sie sich für Formpressen oder Spritzguss entscheiden sollten. Lassen Sie uns diese Verfahren genauer betrachten, um sie besser zu verstehen.

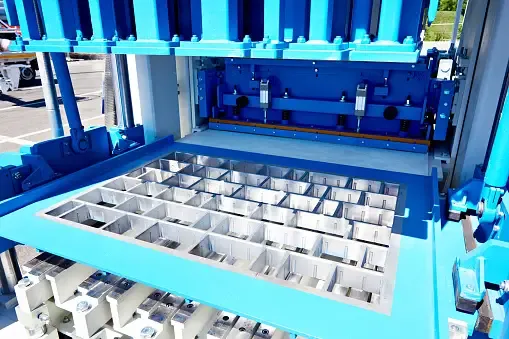

Was ist Formpressen?

Kompressionsformen ist wie Kuchenbacken, nur mit Kunststoff. Wir verwenden Hitze und Druck, um den Kunststoff zu formen. Zuerst geben wir das Kunststoffmaterial in eine Form und erhitzen es. Dann verwenden wir Stopfen, um die Form zu schließen und hohen Druck auszuüben. Diese Kombination aus Hitze und Druck sorgt dafür, dass der Kunststoff die Form der Form annimmt. Dieses Verfahren eignet sich hervorragend für die Herstellung robuster und stabiler Teile mit einfachen Formen.

Zu den im Formpressverfahren hergestellten Produkten gehören unter anderem Autoteile wie Armaturenbretter und Lüftungsschächte, Baumaterialien wie Dachziegel sowie Alltagsgegenstände wie Spielzeug und Haushaltsgeräte.

Die Vorteile des Formpressens

Wenn wir das Formpressen mit dem Spritzguss vergleichen, hat es seine Vorteile. Es eignet sich hervorragend für die Herstellung großer Teile mit einfachen Formen, da es viel Material und Druck aushält. Es ist auch ein Meister darin, viele Dinge schnell und wirtschaftlich herzustellen. Außerdem sind die Teile, die es herstellt, aufgrund des hohen Drucks und der Hitze stark und haltbar.

Die Nachteile des Formpressens

Aber natürlich ist nichts perfekt. Beim Formpressen ist es schwierig, Teile mit komplizierten Formen herzustellen, und es dauert länger als beim Spritzgießen. Außerdem bleibt am Ende etwas zusätzliches Material übrig, das wir abschneiden müssen, bevor wir die Teile verwenden können.

Was ist Spritzguss?

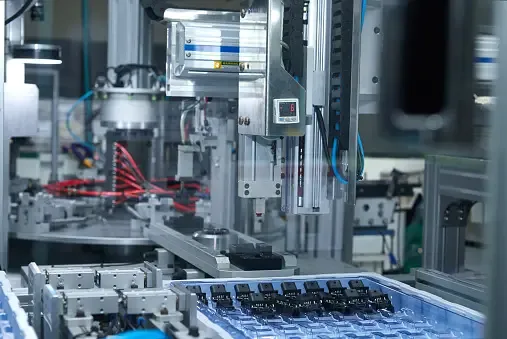

Lassen Sie uns nun über Spritzguss sprechen. Es ist ein bisschen so, als würde ein Plastikkoch geschmolzenen Kunststoff in eine Form spritzen. Eine Schnecke zieht den Kunststoff in einen Trichter und lässt ihn dann durch Hitze schmelzen. Der geschmolzene Kunststoff wird in die Form geschossen, abkühlen gelassen und zack – ist er in der Form fest.

Spritzguss ist wie ein Superheld für die Herstellung detaillierter und präziser Teile. Er eignet sich perfekt für Dinge wie Autogetriebe, Möbel, Spielzeug, medizinische Geräte und Verpackungen.

Die Vorteile des Spritzgussverfahrens

Spritzguss hat einige erhebliche Vorteile. Es können komplizierte Formen mit hoher Präzision hergestellt werden und es funktioniert schnell. In einem Durchgang können viele Teile hergestellt werden und es entsteht weniger Abfall, was gut für den Planeten ist.

Die Nachteile des Spritzgussverfahrens

Aber wie alles andere hat auch dieses Verfahren seine Nachteile. Die Herstellung einer individuellen Form für den Spritzguss kostet Zeit und Geld. Für extrem langlebige Teile ist es nicht ideal, und wenn Sie das Design ändern möchten, kann es teuer werden.

Der Unterschied zwischen Formpressen und Spritzgießen

Der Hauptunterschied zwischen Formpressen und Spritzgießen liegt im Verfahren, bei dem das Rohkunststoffmaterial in die gewünschte Form gebracht wird. Beim Formpressen werden hoher Druck und Hitze angewendet, während beim Spritzgießen geschmolzenes Kunststoffmaterial in die Formhöhle eingespritzt wird.

Ein weiterer Unterschied zwischen Formpressen und Spritzgießen liegt in der jeweiligen Anwendung. Formpressen wird typischerweise zur Herstellung großer und robuster Teile verwendet, während Spritzgießen für die Herstellung komplexerer Komponenten bevorzugt wird.

Beide Methoden haben ihre Vorteile und Kosten. Das Formpressen ist zunächst einmal kostengünstig und eignet sich hervorragend für die Herstellung einfacher, großer Teile. Bei komplexen Formen hat es jedoch Probleme. Spritzguss hingegen ist perfekt für ausgefallene, präzise Teile, erfordert jedoch eine hohe Anfangsinvestition. Auf lange Sicht zahlt es sich jedoch für erstklassige Arbeit aus.

Fazit

Die Wahl zwischen Formpressen und Spritzguss ist wie die Wahl des richtigen Werkzeugs für die jeweilige Aufgabe. Wenn Sie Robustheit und Einfachheit suchen, entscheiden Sie sich für Formpressen. Wenn Sie Komplexes und Präzises wollen, ist Spritzguss die richtige Wahl. Beide Verfahren haben ihre Berechtigung und wir sind hier, um Ihnen bei allem zu helfen, was Sie brauchen.